The planet with all its resources is our most precious asset. From forest to subsoil, from mineral to metal, from sun to fossil energy sources: it all constitutes our natural capital. Milgro wants to create a healthy balance in managing this natural capital. Thereby, industrial symbiosis is an important step in closing raw material chains. In this way, we prevent valuable raw materials from becoming waste and the earth from becoming depleted. In this article, we tell you how 'industrial symbiosis' came about and how it works. You can also read about the benefits and challenges of this approach.

What is industrial symbiosis?

Symbiosis is a term from biology. It refers to a form of society in which two organisms benefit from each other. For example, by exchanging nutrients, energy, materials or information.

Industrial symbiosis is a form of circular economy, in which one company's residual stream is the raw material for another company. Chains of exchange are created. In this process, raw materials and materials are not lost, but are reused again and again. This concept ties in with Milgro's vision in which we prevent raw materials from becoming waste.

The origins of industrial symbiosis

The concept of industrial symbiosis has developed gradually over the years. Since the 1960s and 1970s, companies began experimenting with sharing resources to save costs. This was a response to increasing awareness of environmental problems.

One of the earliest and most famous examples of industrial symbiosis is Kalundborg. In this industrial Danish town, Statoil's refinery shared water with a nearby power plant. This in turn supplied power to other companies. The town was heated with waste heat water from the power plant. Sludge from the refinery was used as fertilizer in agriculture. As the system expanded to businesses in the region, a closed loop was created. A more recent example from our own kitchen is that of a phosphate-rich residual stream from a factory that we converted as a phosphate source for water treatment.

How does industrial symbiosis work?

Nature is an important source of inspiration for industrial symbiosis. With closed cycles, nature itself is a master at efficiently reusing resources. Industrial symbiosis mimics the cycles we see in ecosystems. Nothing goes to waste; everything has a function.

For industrial symbiosis to succeed, good cooperation between companies is crucial. Understanding waste streams as well as excess materials, energy, water and byproducts is essential. A crucial principle is that one company's waste becomes the resource for another. Thus, industrial symbiosis not only reduces the need for new raw materials, but encourages reuse, thereby reducing costs.

Benefits of industrial symbiosis

Industrial symbiosis offers several advantages:

- Preserving the value of raw materials through reuse

- Reducing waste

- Reduce costs

- Reduce purchase of virgin materials

- New opportunities

The earth benefits from the more efficient use of natural resources. Reuse of raw materials leads to more environmentally friendly operations, creating significantly less waste and pollution. The entire society thus benefits from fewer negative environmental impacts.

In addition, industrial symbiosis offers companies economic benefits. Reusable materials are often cheaper than new raw materials. Moreover, valuable raw materials no longer become waste. Thus, the process can provide cost savings in several areas. In addition, industrial symbiosis offers new business opportunities and revenue streams: opportunities arise to develop new products and services that would otherwise not be feasible.

With our extensive network of waste disposers, we can act as matchmakers, making ideal connections between waste and raw materials, which is at the heart of industrial symbiosis.

Challenges and considerations

Industrial symbiosis is a promising concept that puts the circular economy within reach. Yet companies still need to address a number of challenges and considerations to implement it successfully.

Matchmaking

A crucial challenge in realizing industrial symbiosis is finding the perfect match between different streams. How do you guarantee that what is waste for one company seamlessly matches the needs of another company as a valuable raw material? This complex issue requires deep understanding and extensive networking capabilities.

Herein lies the strength of a party like Milgro. With our extensive network of waste disposers, we can act as matchmaker, creating the ideal connections between waste and raw material, which is at the heart of industrial symbiosis.

Regulatory and obstacles

Regulatory and logistical barriers also often complicate the implementation of industrial symbiosis. Complex legal issues can arise when sharing resources and reusing materials between companies. Regulations can sometimes be an inhibiting factor in this. It is necessary to overcome these obstacles through careful planning and consultation with government agencies. In this, too, Milgro can advise you.

Industrial symbiosis in the future

Worldwide, there is growing attention to and increasing implementation of industrial symbiosis. Of course, concerns about climate change and natural resource depletion play an important role in this.

In addition, interest in industrial symbiosis is growing because of the shift to a circular economy. This seeks to minimize waste by keeping products and materials in the economy as long as possible. Industrial symbiosis fits perfectly within this model.

Learn more

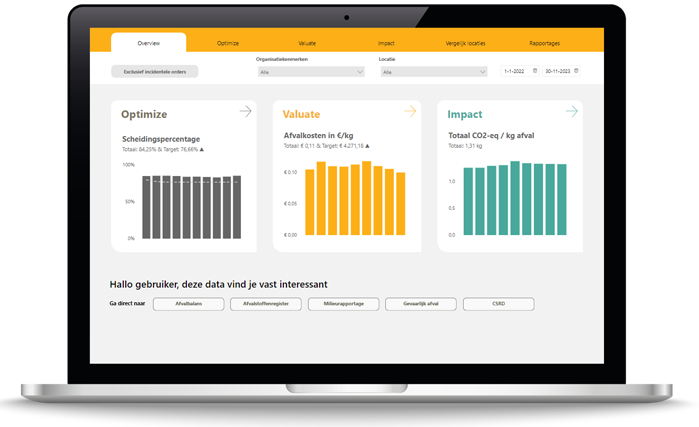

As your ultimate matchmaker, we make the perfect link between waste and feedstock - the heart of industrial symbiosis - thanks to our extensive network of waste disposers. We also offer deeper insight into your waste streams and their potential with our innovative online tools.

Want to know more? Book an appointment

Stay informed

Stay up to date on all new developments? Follow us on LinkedIn or Instagram. Or subscribe to the newsletter. Are you curious about what Milgro can do for your operations and waste process? Contact us