A Life Cycle Assessment (LCA) measures the environmental impact of a product during all life phases of this product in a quantifiable way. From the extraction of raw materials to make the product to the processing of waste that is released during production up to the end-of-life phase and all phases in between. An LCA analysis often aims to take a major step towards sustainability, among other things by weighing up options. Because what is more sustainable if you include all life phases in the calculation? Electric or petrol driving? Eating soy products or meat? Send an e-mail or print your message and send it by post?

Taking all factors into account

These questions are not easy to answer without considering the many factors that influence the impact. At first sight, for example, sending an e-mail seems much more sustainable than making a printout, putting it in a paper envelope and having it transported via a, in the favorable case, CO2-neutral delivery van. But sending an e-mail also has an impact if you think of the data center that is needed for this and the amount of power and cooling water that it uses. And don't forget the footprint of building such a huge data center. These at first glance hidden factors all have influence. And this is relatively small for the processes above, but can make a big difference for large-scale processes.

The goal of LCA

Life Cycle Assessment is an internationally recognized framework that calculates the ecological footprint of a product, based on internationally established standards. Motivation for the use of LCA is often the desire to comply with the guidelines of suppliers and customers or the organization itself wanting to take responsibility for the ecological footprint caused. The outcome of an LCA can be presented in an environmental profile, which shows in which phases of the process the environmental effects will be greatest. And what can best be optimized for. This environmental profile is also known as EPD (Environmental Product Declaration).

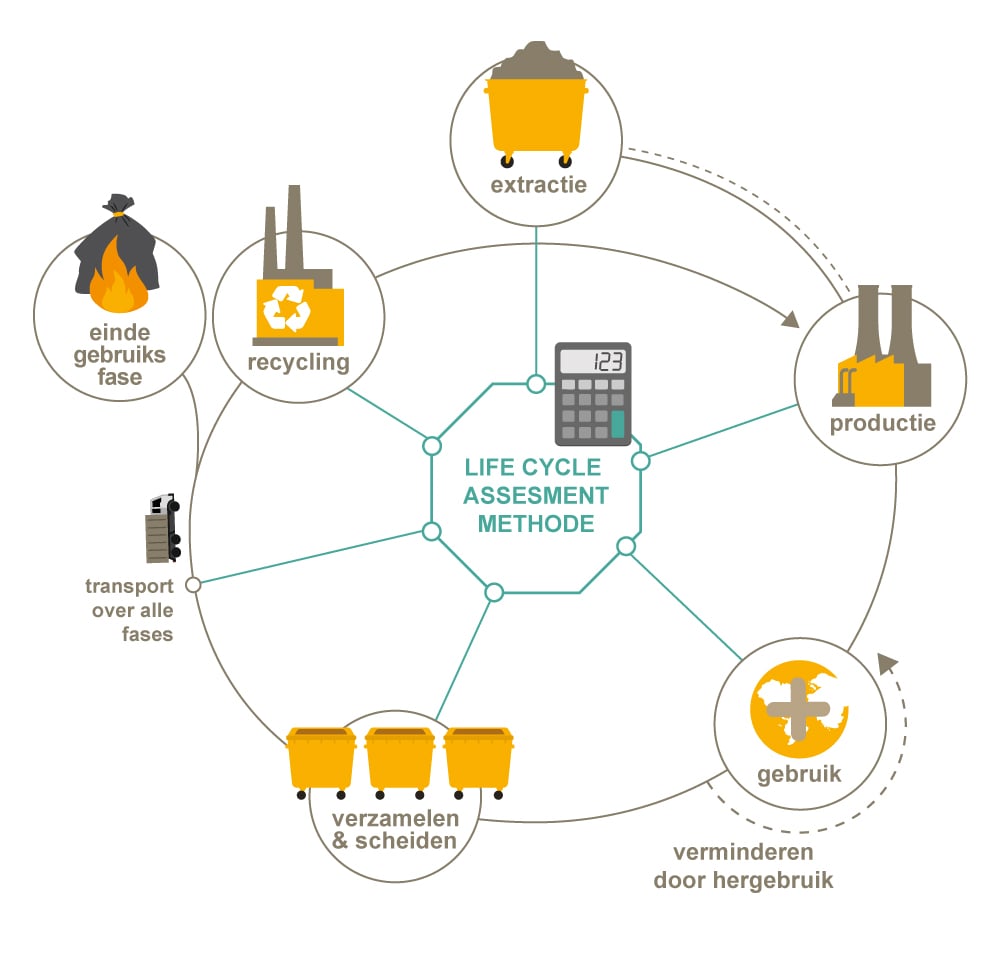

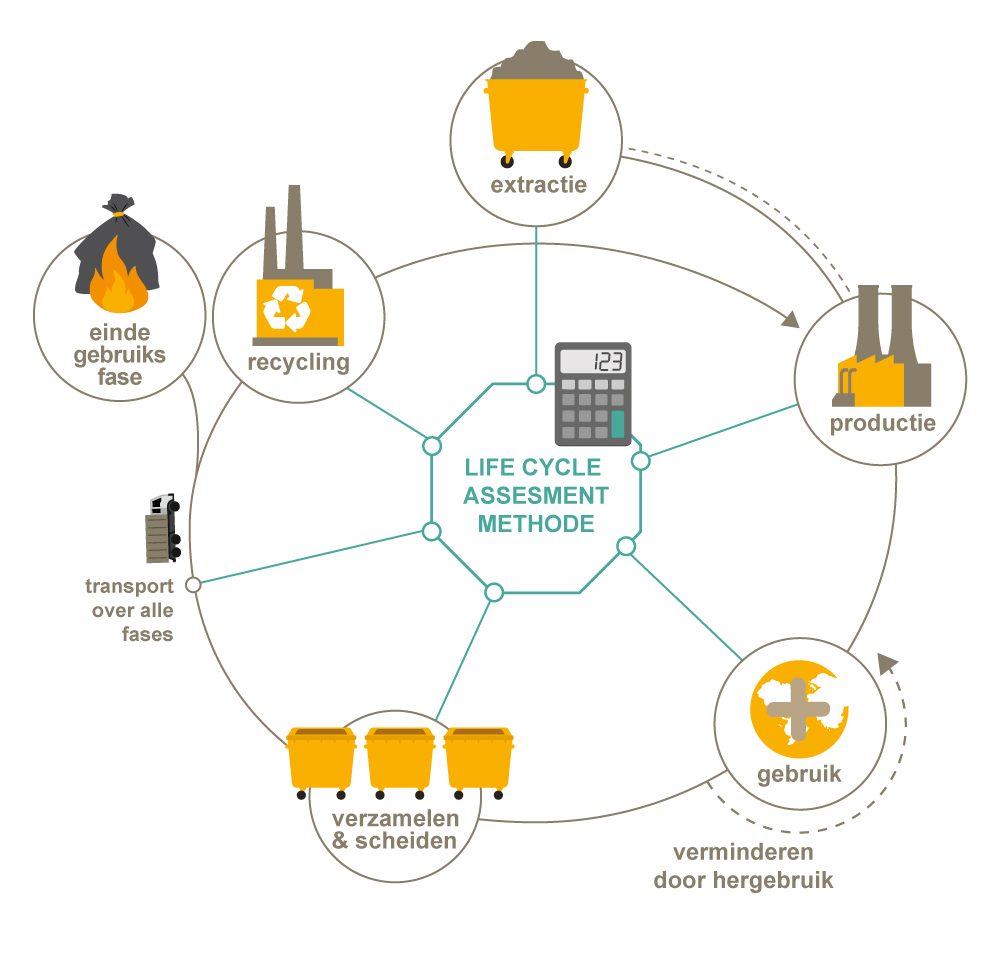

Product lifecycle model

The LCA method, which Milgro uses in its calculations, is based on five life phases. We call this the Product Lifecycle (PLC) model. Each phase has its own impacts. Because LCA includes all phases in the calculation, you prevent impacts from being shifted from one phase to the other. There are examples of a favorable effect on the CO2 balance by converting residual flows from a processing process into energy production by means of combustion. This favorable effect is achieved because this energy production from residual materials is compared with extraction from fossil fuels. A pretty linear thought. By including all phases in the calculation, this shift cannot take place. And residual flows retain their value as raw materials; the basis of the circular idea.

The life stages of LCA are

- Extraction of raw materials

- Production

- Use

- Collection and separation of waste

- Final disposal or recycling

Transport is included in the calculation of all phases

Steps in an LCA

Steps in an LCA

- Determining scope: what do we take with us and, above all, what do we not take with us? You can dig so deep that there is a risk that the assessment will never be completed. After all, there is always something new to retrieve. The scope set in the EPD plays a major role in this.

- LCI (Life Cycle Inventory): collecting and quantifying data using LCA databases. When no data is available, industry averages are used.

- LCIA (Life Cycle Impact Assessment): in this all data and indicators are translated into the intended impact category. An example of this is CO2 emission / Global warming potential

- Interpretation and validation of the data, as described in the ISO14040 and ISO14044 standard

- Apply in procurement, product development, strategy, policy, operations, etc.

Criticism of the method

As with many methods, there is also criticism of the use of LCA. For example, when existing databases are not sufficient, averages from the sector are used. This is where incorrect use of data can creep in. Also, due to the lack of mandatory regulations and the correct use or omission of certain data, the outcome can be attributed to the advantage of the producer. However, these stumbling blocks can be overcome by deploying a specialist agency and validating the data using ISO standards.

Long term vision

Also within an LCA it is important to keep looking at the bigger picture. LCA calculates the impact of an existing product, but is also based on a comparison with alternatives. Think back to the examples from the first paragraph. The conclusions from an LCA analysis are sometimes surprising. For example, driving an average electric car is more sustainable, after 70,000 km. A vegetarian meal more environmentally friendly than eating meat, by takingimpact versus nutrition into account. And sending an email costs more CO2 than sending a letter by post. Especially if you also keep the email for some time.

Closed loop

From that point of view it is still good to make a comparison. After all, a completely different product can be a much more sustainable alternative than optimizing the existing production process. A good standard to use here is the degree of circularity. How we make the entire chain closed loop. How we ensure that sustainable waste management eventually becomes sustainable resource management. And how we maintain and preserve our natural capital for the long term.

About Milgro

Milgro provides insight, overview and continuity in sustainable waste and resource management, thus unburdening its clients. We use, among other things, validated and objective LCA data to calculate impact for our clients and partners, as visible in our updated CO2 report, for example. With the acquired insight, together with our technology, methodology and approach, we enable organizations to successfully implement the resourcetransition. The result is profitable sustainability: earn & earth together.

Get in touch or get additional information

We would be happy to tell you more about our sustainable waste and resource management without obligation. Click here and we will contact you as soon as possible.

Stay informed

Stay up to date on all new developments? Follow us on LinkedIn or Instagram. Or subscribe to the newsletter. Are you curious about what Milgro can do for your operations and waste process? Contact us.