Measuring emissions from waste is an important part of the GHG protocol. Different methods are used for this purpose. In this article we compare the way the Greenhouse Gas protocol measures emissions from waste with Milgro's approach. Find out how these approaches relate to each other and how Milgro helps your company reduce your carbon impact.

We'll start at the beginning first: the Greenhouse Gas (GHG) protocol To address climate change, understanding greenhouse gas emissions is indispensable. That's why the GHG was created: a standardized approach to quantifying emissions. The protocol offers (government) agencies and companies a data-driven approach to monitoring CO2 emissions.

The Greenhouse Gas protocol and emissions measurement of waste

The broadest category of greenhouse gas emissions falls within what is known as scope 3 of the Greenhouse Gas protocol. This includes all other, indirect emissions resulting from an organization's activities. In scope 3, emissions from recycling can occur both back and front of the chain: an organization can use recycled materials or produce its own waste that can be recycled again. But end-of-life emissions from the end user, when it becomes waste, also fall under scope 3.

The Greenhouse Gas protocol provides guidelines that allow you to properly track emissions from these materials within scope 3.

Who reports in scope 3?

Emissions are released during the recycling of waste streams, also referred to as the Cradle to Gate emissions of recycled material. Obviously, recycling companies record these emissions in their scope 1 and 2.

But who in the chain reports these emissions in their scope 3? The producer of the recyclables? The company that sends the waste to the recycling company? Or the company that puts the recycled material back into production? To answer this question, we need to dive deeper into the GHG protocol.

But who in the chain reports these emissions in their scope 3? The producer of the recyclable products? The company that sends the waste to the recycler? Or the company that puts the recycled material back into production?

The GHG Protocol guidelines can be summarized in three core principles:

- Companies report in scope 3 emissions from waste treatment of their own waste (upstream scope 3 because waste treatment is a service purchased) but also end-of-life waste streams (downstream)

- Cradle to Gate emissions from recycling are reported in scope 3 by the company purchasing the material. We call this principle the recycled content method

- Companies must also report on emissions from waste disposal in the end-of-life phase; that is, the waste generated at the end-user. Design choices can make recycling easier or possible which reduces emissions from waste in this phase.

There is thus a cut-off point at the time of recycling in which emissions from the first life cycle do not count towards the second life cycle. This becomes clear using an example::

Example:cookies baked too brown

A mistake is made in a cookie factory. The temperature was too high and the color of the cookies does not comply with the applicable guidelines. They end up in the waste and are offered to a processor who turns them into pig feed. What does this mean for the calculation in scope 3?

For the cookie factory: The factory knows that the pig farmer reports emissions from recycling in scope 3. Only emissions from transportation to the feed producer can optionally be included in scope 3.

For the feed producer: Emissions from recycling are part of scope 1 and 2 for him. The feed producer can advertise this feed as circular pig feed with very low emissions.

For the pig farmer: Reports on emissions from the purchase of cattle feed. Emissions from cookie production do not count here.

Conclusion from the example

All three parties can rightly commend themselves for making sustainable choices. What if the cookies, although baked too brown, were still edible but just did not meet the aesthetic requirements? Wouldn't the most ecological choice have been to still use the cookies for their intended purpose? Namely, for human consumption.

When using resource use as a benchmark, it is good to look beyond just the direct costs. The GGP calculation only looks at emissions. We also look at the use of raw materials and how you use them.

Avoided emissions (scope 4) and why they are less sustainable than they sound

Companies may choose to report emissions on "avoided emissions," sometimes called scope 4. Avoided emissions or avoided emissions are greenhouse gas emissions that are prevented through the implementation of sustainable practices or technologies. In the case of waste recycling, these are emissions avoided by using recycled materials instead of virgin raw materials.

That sounds positive. Yet products with large avoided emissions are not always the most sustainable. Back to the example of the overly browned cookie. The cattle feed producer may tout for the circular cattle feed the emissions avoided by not having to use "virgin" corn, grain or soy. But in the emissions from the pig feed, the cattle feed producer does not have to take into account the emissions from producing the cookie to brown.

Moerman's ladder shows that producing animal feed from food waste is and good, circular solution. But to really steer economical use of our raw materials, our natural capital, we need an additional perspective on the emissions as reported within the GHG protocol. This immediately exposes why Milgro chooses a nuance on the calculation of emissions from waste and residual streams.

But to truly steer economical use of our resources, our natural capital, we need an additional perspective on emissions as reported within the GHG Protocol.

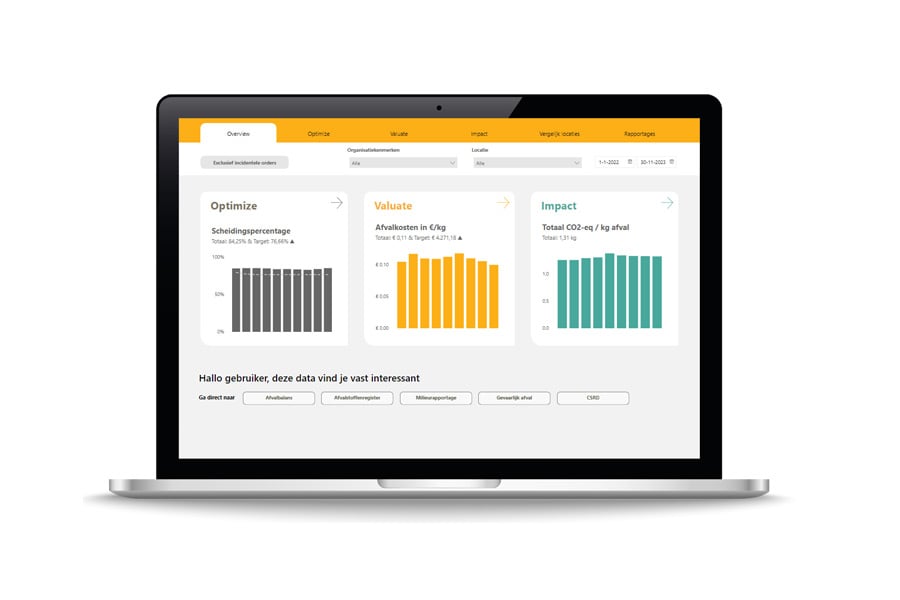

Milgro and measuring emissions from waste

Milgro takes a holistic circular approach to measuring emissions from waste and residual streams. We highlight the full life cycle of raw materials, including emissions from recycling and avoided emissions. In this way we provide a complete picture of emissions from waste streams offered for recycling. The total emissions we assign to a waste stream are built up from the following four life phases:

- Production: the mining and processing of raw materials, materials or products

- Transport: from the discarder of the waste to the processor

- Processing: the emissions resulting from the waste treatment or recycling process.

- Avoidance: prevented emissions by utilizing secondary raw materials rather than virgin (virgin) raw materials.

Advantages of the Milgro approach

This approach offers a large number of advantages. We summarize them:

- The method provides insight into the benefits of recycling, but also puts them in relation to innovations that result in less waste. The calculation rewards the choice that is higher on the r-ladder and the choices can be compared.

- It becomes clear for which raw materials there are many environmental gains to be made by recycling. And for which raw material streams the recycling process has relatively little environmental gain. This is because emissions from the recycling process hardly outweigh emissions from the use of recycled raw materials. A good example ise glass or steel. These streams can be fully recycled. However, this takes a lot of energy. With Milgro's CO2 analysis, a well-considered strategy can be made for each waste stream.

Would you also like more insight into your waste management?

In this article you read about the different approaches of the GHG Protocol and Milgro around measuring emissions in waste streams. Do you want more insight into your waste management and emissions? Then combine the waste measurements of the Greenhouse Gas protocol with the broad approach of Milgro. This will give you a complete picture of your CO2 impact. This provides a good basis for effectively reducing your emissions.

Stay informed

Stay up to date on all new developments? Follow us on LinkedIn or Instagram. Or subscribe to the newsletter. Are you curious about what Milgro can do for your operations and waste process? Contact us