Waste incineration and circularity are rightly seen as contradictory. Yet within the CSRD, this form of processing may in many cases be reported as "recovery.

What does this mean for your reporting? And how does this classification relate to other models, such as the Ladder of Lansink? We explain in this blog.

How does the CSRD look at waste incineration?

Waste incineration can-under conditions-be seen as a 'useful application' within the CSRD. The condition is that the incinerator has a so-called R1 status. This status is laid down in the European Waste Framework Directive (2008/98/EC) and is intended for plants that recover energy from waste. That is, heat is released during waste incineration. That heat is captured and converted into energy, for example for the production of electricity or for heating homes via district heating. If the plant recovers enough energy from the waste according to the European Standard, the process is classified as energy recovery.

Only incineration plants that achieve this efficiency may be recognized as R1 plants and thus fall under the heading of "recovery" in the CSRD system.

In practice, this means that virtually all waste incineration plants (AVIs) in the Netherlands and Belgium fall under this R1 classification. As a result, companies may classify the waste processed through these plants under 'useful applications', the same category as recycling, within their CSRD reporting.

For reporting purposes, this means that a large proportion of residual waste may be formally considered 'beneficially processed' as long as it is processed at a facility with R1 status.

How waste incineration is assessed in other models

Although waste incineration with an R1 status formally falls under "recovery," that does not align with how various companies and models view circularity.

No materials are retained or recovered in incineration. The energy released is utilized, but the raw materials themselves are lost. From a circular perspective, this is seen as a loss of value because there is no reuse or recycling.

Therefore, in models such as the Lansink Ladder, incineration falls under energy recovery: a lower rung than reuse or recycling. Also, the R-ladder and models such as CTI (Circular Transition Indicators) generally do not classify incineration as circular.

What changes in practice?

With the classification of waste incineration as "recovery" within the CSRD, companies can count on relatively high percentages of "recovered" waste in their reporting. Especially when a large part of the residual waste is processed through a waste incinerator with R1 status, this percentage can reach 90% or more.

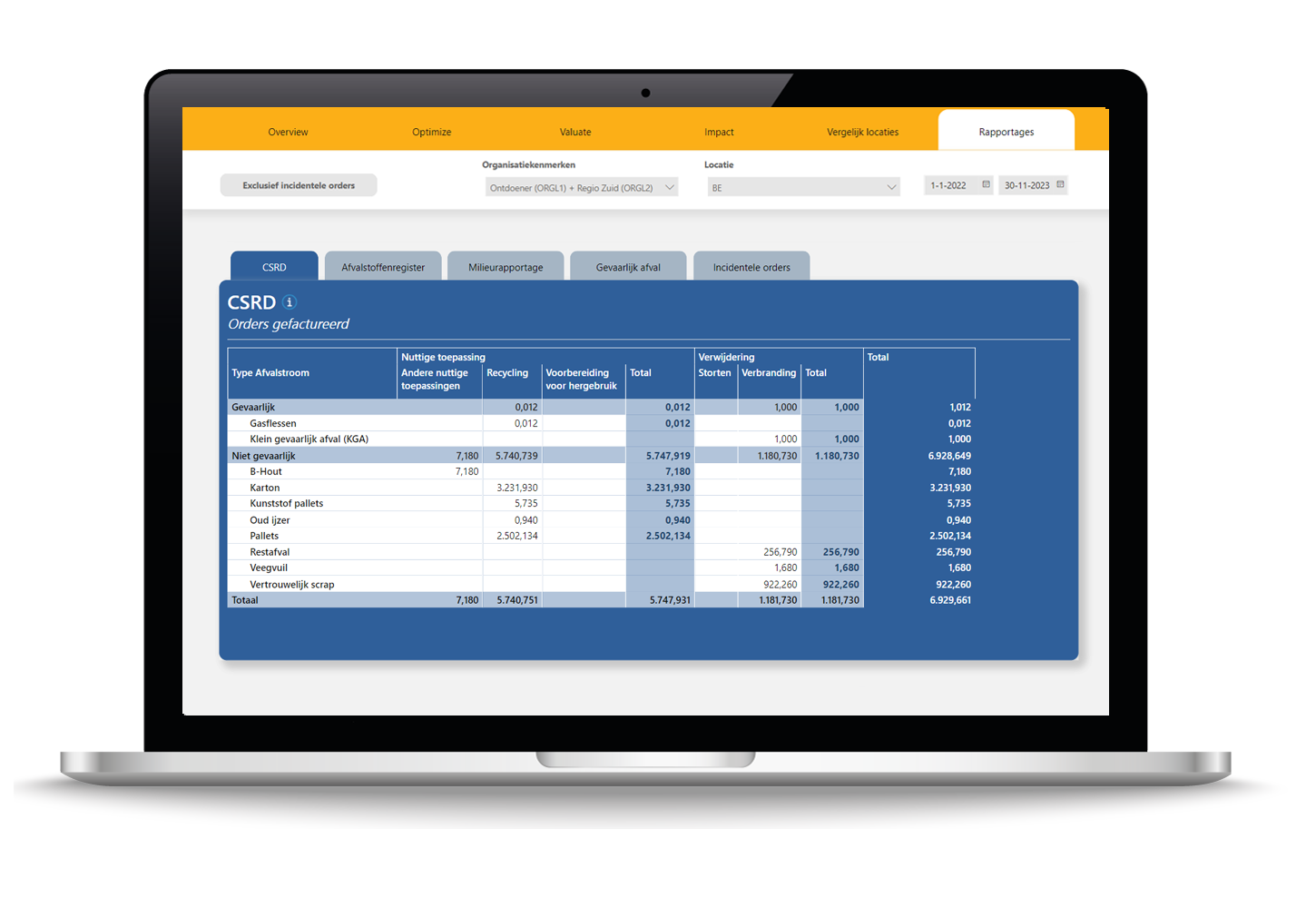

In our records of waste processing, until recently Milgro did not distinguish between waste streams incinerated at Waste Incineration Plants with and without R1 status. As a result, waste incineration-regardless of the amount of energy recovered in the process-was included entirely under "disposal" in our dashboard, which did not fully align with the requirements of the CSRD.

We have since changed this. In our dashboard we now distinguish between the two forms, so that waste incineration with energy recovery is correctly reported under 'recovery'. This makes the figures legally correct but does not mean that we agree with the classification.

How does Milgro view this?

At Milgro, we believe that waste is a raw material that has lost its way. From that perspective, we do not see incineration as a circular process. The materials are lost and with them the potential to reuse them in the chain. We therefore do not fully agree with the classification of waste incineration as "recovery" under the CSRD.

In our dashboard we therefore not only show processing streams according to the CSRD classification (in our CSRD report), but also based on the Ladder of Lansink. In addition, the specific processing can be viewed and the greenhouse gas emissions (CO2eq) of each waste stream are insightful. This not only gives organizations insight into how much waste receives a useful application in accordance with the CSRD, but also into exactly how high quality their waste processing is. To truly steer for circularity, we advise our clients to not only focus on the percentage of useful application, but especially on separation percentage, average CO2eq per kg of waste, and volumes of reused and prevented waste streams.

Try the Milgro Dashboard free for 7 days.

The CSRD sets clear requirements for waste reporting. Our dashboard helps you meet these requirements in a concrete and insightful way—distinguishing between processing methods such as waste incineration with or without energy recovery.

Try the Milgro Dashboard free for 7 days.

Stay informed

Want to stay up to date with all the latest developments? Follow us on LinkedIn and Instagram or subscribe to our newsletter. Curious about what Milgro can do for you operation and waste process? Feel free to get in touch.