This week is Verspillingsvrije Week (Food Waste Week). The week is meant to prevent food waste. This is necessary, because a quarter of our food is wasted in the Netherlands every year. That's 2 billion pounds! Controlling waste is the key to reducing it. Companies have that key in their hands, provided they work smartly together in the chain and bear joint responsibility. How does Milgro view waste?

What is food waste?

Food waste occurs when food intended for human consumption is not used for this purpose. Moerman's ladder defines a number of steps of valorisation of food, including donation, use as animal feed, fermentation, composting, incineration and dumping or discharging. Accurately knowing the cause of waste is a precondition for tackling and reducing it.

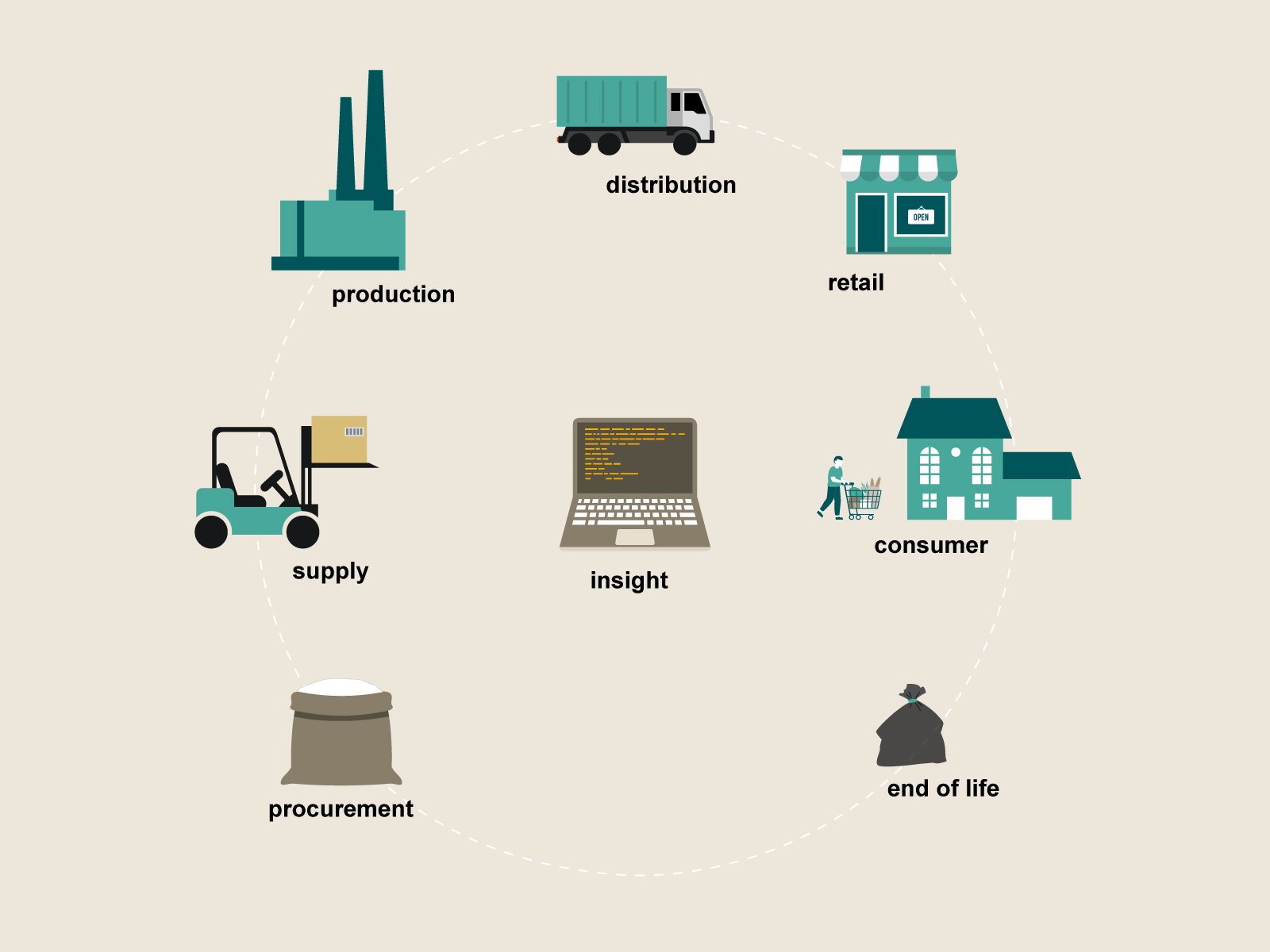

Waste throughout the entire production chain

The causes of waste can be found everywhere in the chain; from the purchase of raw materials and how these raw materials are transported and supplied, through production, packaging and consumption. For purchasing, suppliers generally manage how they supply their raw materials and in which packaging. Supplying the right volumes of raw materials in standard packaging that is easy to reuse minimizes waste.

There is also waste in the production processes. For example, due to slightly different weights, breakage or loss of cutting. Many companies have smart solutions for re-introducing raw materials or semi-finished products from cutting loss into the production process, so that waste due to cutting loss in this part of the chain is kept to a minimum.

Another cause of waste in the production process is a lack of proper coordination between producer and customer. For example, strict requirements are imposed on the expiry date of a product. If a producer cannot comply with this, or a customer does not accept a deviation, products are left behind, which creates the risk of waste. Strict demands on quality or aesthetics can also encourage waste. For example, it happens that fresh products that look slightly different are not purchased by a retailer. It is important that producer and customer take supply chain responsibility together in order to minimize waste in this part of the production chain.

Taking supply chain responsibility to reduce consumer waste

Fortunately, there are more and more initiatives to preserve these types of products for human consumption. Think, for example, of Too Good To Go, a platform that is not only used by consumers, but also by producers, retailers and catering. Or to InStock. This is a wholesaler that sells good fresh produce that would otherwise be thrown away. A bent cucumber can be used in a healthy sandwich, a fruit salad tastes no different with pieces of straight banana in it. There are also more and more products made from residual flows, such as beer made from old sandwiches, or fresh pasta sauce made from twisted tomatoes.

Security of supply and overproduction

Waste due to overproduction is unfortunately still too common. In order to offer a buyer security of supply, there is a risk that a producer will produce too much volume, as a result of which products remain on the shelves and do not reach the consumer. This risk is smaller when delivering to online retailers; they do not have to have full shelves all the time, and can therefore tailor their offer more specifically to consumer demand. In this case too, producers, suppliers, retailers and other chain partners must jointly take responsibility for the waste that can occur at the consumer. This saves wastage in the production process, and certainly also for the consumer.

More intelligence about consumer behavior is needed

It is crucial that the business community collectively gains greater clarity about consumer behavior about when they have what needs. Intelligence about consumer behavior will have to increase. With that intelligence, other choices can be made, or innovations can be devised to prevent waste. An example of this is the provision of fresh frozen bread in the supermarket, so that bread does not have to be thrown away after a day.

The size and type of packaging also play a role in reducing waste. The tension between sustainability on the one hand and food waste on the other means that packaging choices are not exactly easy. The less plastic used in the packaging, the better for the environment. However, this increases the risk of products spoiling more quickly. It is a good sign that developments around biobased, recycled and biodegradable plastic packaging are following each other at lightning speed. Manufacturers are eager to adopt these sustainable packaging innovations.

Any business that communicates directly with consumers has a job and responsibility to help consumers waste less. This is possible with good information, such as, for example, on the difference between a BBD (best before date) and BBE (best before end) dates. And smart packaging choices. When packaging with easily separable mono materials is manufactured, consumers are helped with better separation with the right instruction.

Smart packaging choices and knowledge of the recycling market

It is also important for manufacturers, retailers and other chain partners to join forces with regard to product packaging. This is necessary to gain joint insight into and knowledge about the recycling market. The business community needs to know what the options are for recycling product packaging. Can packaging be recycled at all, and if so, how, chemically or mechanically? Is there already a market for a certain type of plastic in the recycling market? And how much energy does it cost to recycle a certain flow of plastic product packaging? Coordination on this part of wastage is necessary. This requires a government that directs and co-invests in the best developments in the field of plastic recycling.

Tips for taking measures against food waste in the workplace:

- Identify what food waste consists of through technology, smart cameras and measuring systems. This provides insight into which products are thrown away, what it weighs and how much it costs.

- It turns out that recognizable colors and icons help best when separating waste. So, blue for paper. And green for organic waste. So do not try to stimulate waste separation with your own house style or icons that you devised yourself. You also make separation easier by placing the separation bins closer and residual waste bins furthest away

- Control helps; if the facility service provider is present on the work floor, visibly picks up the different groups and confronts employees about their behaviour, this pushes up the divorce rate.

- The role of sustainability manager is important. This makes the effects of better waste separation in the workplace visible.

- Milgro provides training and uses gamification to increase the divorce rate. With effect: on average, the amount of unsorted waste at Milgro's clients is reduced by 30 to 40 percent. Many millions of kilos of raw materials are thus saved from the incinerator..

Why fight food waste?

The Verspillingsvrije Week is intended to reduce waste in all links of the chain, from the production process to consumer behaviour. Together we achieve more. If we work together, we can make the Netherlands one of the first countries to cut food waste by half. In this way we contribute to achieving the Sustainable Development Goal 12.3 and we keep 1 billion kilos of good food within the chain every year.

In addition, we achieve a significant CO2 reduction with this. Rabobank has calculated that if we achieve this target, we will reduce our footprint by 3.1 million tons of CO2 equivalent per year. This is equivalent to not letting 666,000 passenger cars drive for a year. we cost if we fight food waste. The University of Wageningen calculated all food wasted in the Netherlands per year: 2.2 billion kilosk! Combating food waste is good for the world and for your wallet.

Milgro and food waste

The fight against waste starts with knowing what is in the containers and in the waste bins: control over waste. Digitizing the waste process provides insight into what waste is and which flows these are. This also shows whether the flows are properly separated. Once a company has a good idea of the size of the different flows and the causes of waste, the waste processes can be optimized and waste can be reduced. With the right tools and support, companies are able to analyze the data of their waste streams, in order to subsequently take effective measures. From a grip on waste to a grip on waste.

Milgro's methodology starts with the focus on the output; get a grip on the waste process. This provides the insight with which the process is optimized and waste is reduced. For Milgro, this is a step towards the ultimate goal: to implement a circular business operation, in which we close raw material chains in a way where earth and earn are in balance.

Ready for a first step?

Do you lack sufficient insight to manage waste flows and to direct the entire waste process? If you want to know exactly where your organization stands and want to monitor and report on results, then digitization is the solution.

Stay informed!

We regularly publish articles and blogs about digitizing the waste process, insight into waste and recource flows and the circular economy. Follow us onLinkedIn.